|

Definition of Stainless Steel :

Stainless steel contains chromium (Cr) which will form dense chromium oxide (Cr2O3) membrane

on the surface to prevent continuous corrosion of steel. It has excellent features such as anti-

corrosion, anti-oxidization, low heat conductivity and good processing properties.

Widely speaking, stainless steel is a specific kind of steel with corrosion resistance and heat

resistance. The chromium content is between 10.5% - 30%.

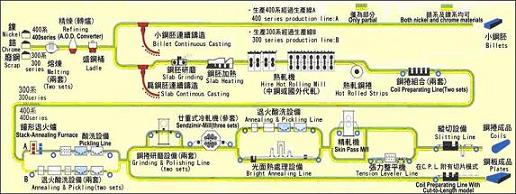

Production Flow Diagram

BENEFITS OF STAINLESS STEEL

1. Excellent corrosion resistance

2. High strength and durability

3. High pressure capability

4. Hygiene

5. Ease of jointing

6. Good Appearance

7. No Maintenance

8. Recycling

9. Environmental Friendly

APPLICATIONS

1. Household Plumbing System

2. Commercial Building Water Supply System

3. Potable Water Treatment Plant

4. Wastewater Treatment Plant

5. Cleaning System

6. Irrigation System

GRADE OF STAINLESS STEEL

The following table lists the designation for specific types of 304 and 316 grades of stainless steel

and also provides their compositions. 304 grade often specifies for all general purpose

application. 316 grade is basically a 304 grade enhanced by the addition of 2-3% Molybdenum.

Containing large amounts of Molybdenum (Mo) grade (Type 316) are preferred to use in

corrosion environment, higher seawater resistance than 304, also can perform excellently in all

hot and cold water with chloride contents up to 200ppm.

The low carbon version is designated with "L" after the alloy number (304L or 316L) are

preferred to use when welding is the joining method.

Table of the Chemical Composition of Stainless Steel

|

Steel Grade |

Chemical Composition |

Physical Requirement |

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Yield Strength |

Tensile Strength |

Elongation |

|

% |

% |

% |

% |

% |

% |

% |

% |

(N/mm2) |

(N/mm2) |

(%) |

|

304 |

0.03 |

1.0 |

2.0 |

0.045 |

0.03 |

9-12 |

17-19 |

- |

215 |

480 |

40 |

|

304L |

0.07 |

1.0 |

2.0 |

0.045 |

0.03 |

8-11 |

17-19 |

- |

230 |

490 |

40 |

|

316 |

0.03 |

1.0 |

2.0 |

0.045 |

0.03 |

11-14 |

16-18 |

2-2.5 |

225 |

490 |

40 |

|

316L |

0.07 |

1.0 |

2.0 |

0.045 |

0.03 |

10-13 |

16-18 |

2-2.5 |

240 |

510 |

40 | |